Usted está aquí

Growing MSC in Bioreactors: Part 2. Microcarriers

When the goal is to develop a robust manufacturing method for MSC production, several factors need to be considered, as discussed in Part 1 of this series. The adherent nature of MSC requires the presence of a surface for the cells to attach to during growth. If this surface is not present, the MSC would die through a processed named anoikis [1].

While different bioreactors address the need for a growth surface from different angles, in stirred tank bioreactors, “microcarriers” provide the surface where the cells will attach and grow. Stirred tank bioreactors (STR) are very common in the biochemical engineering industry. For example, the most commonly used cell line for the industrial production of antibodies is Chinese hamster ovary (CHO) cells, and CHO cells used to be expanded on microcarriers before they were modified to be able to grow in suspension[2].

While different bioreactors address the need for a growth surface from different angles, in stirred tank bioreactors, “microcarriers” provide the surface where the cells will attach and grow. Stirred tank bioreactors (STR) are very common in the biochemical engineering industry. For example, the most commonly used cell line for the industrial production of antibodies is Chinese hamster ovary (CHO) cells, and CHO cells used to be expanded on microcarriers before they were modified to be able to grow in suspension[2].

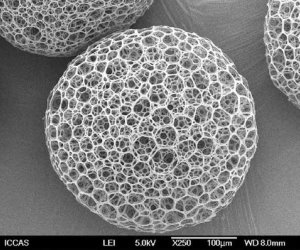

But what exactly are microcarriers? They are small beads with diameters between 100 and 250 µm that are manufactured from different materials such as polystyrene, dextran, and porcine gelatin, among others [3]. Microcarriers are the matrix on which anchorage-dependent cells are able to grow.

Here are some important properties of microcarriers:

- Microcarriers can be classified as non-porous or porous [4]. Cells can only grow on the surface of non-porous microcarriers, whereas porous microcarriers allow cells to also grow inside. The porous microcarriers have a higher surface area per unit of volume than non-porous ones and this enables a higher cell density to be achieved during growth [3]. However, there is a trade off because separating cells from the inner surface of porous microcarriers is more difficult than retrieving cells from non-porous microcarriers.

- Microcarriers for the growth of MSC are either positively charged or non-charged, because mammalian cells such as MSC carry negative charge.

- Although microcarriers can be manufactured from different materials [3], as we move towards robust manufacturing of MSC it is desirable to avoid microcarriers containing components of animal origin in order to improve batch to batch consistency [5].

- To avoid the complications of harvesting, newer microcarriers are biodegradable, but so far only one publication has used them to expand MSC [18].

- The choice of microcarrier is key to the success of MSC growth in stirred tank bioreactors, because the attachment phase between MSC and microcarriers is critical for the success of the expansion process. Several studies have been conducted to identify the ideal microcarrier that optimizes MSC yield and MSC quality [3], [6], [7].

Once the microcarrier type is chosen, the next step to start the growth of MSC in the STR with microcarriers is the attachment phase [8]. The attachment phase brings together the microcarriers and the cells to initiate the cell culture. Several options can be found in the literature to perform this process [8]–[10]. The goals in the attachment phase are to promote contact between cells and microcarriers, but to also provide some level of agitation that maximizes the number of cells coupled to the microcarriers. When the attachment phase is optimized, attachment efficiencies can reach values above 90% [5], [11].

As the MSC expansion proceeds, the cells will multiply on the surface of the microcarriers. Once the surfaces of the microcarriers are covered, bridges of cells start forming between microcarriers. At this point a decision must be made about how long to continue the culture. If it is desired to continue the expansion, more microcarriers can be added to the bioreactor to provide more surface area for MSC growth; this technique is called bead-to-bead transfer [12].

Eventually the expansion is complete, and then the cells and microcarriers must be separated, in order to have a final MSC product that is purely cells. This is done in two steps: first the growth medium is removed, and second the cells are separated from the microcarriers [13], [14]. The medium is usually removed by stopping the agitation and aspirating the liquid. The separation of cells from microcarriers uses a sequence of enzymatic treatments followed by filtration [15]. The enzymatic solution used to separate microcarriers from cells is usually trypsin EDTA or TrypLE. The advantage of TrypLE is that it is free of animal components and thus meets cGMP regulatory requirements, whereas trypsin EDTA is from an animal origin. Additionally, use of an enzyme that is xeno-free ensures less batch to batch variability.

In summary, when expanding adherent cells like MSC in STR bioreactors using microcarriers, the choice of microcarrier is critical to optimize cell yield and cell quality. The attachment of cells to the microcarriers can be assessed by the attachment efficiency [16], while the potency of the final cell product can be assessed with CFU-f assay or T-cell inhibition proliferation assay [17].

References

- A. P. Gilmore, “Anoikis,” Cell Death Differ., vol. 12, pp. 1473–1477, 2005.

- Z. Xing, B. M. Kenty, Z. J. Li, and S. S. Lee, “Scale-up analysis for a CHO cell culture process in large-scale bioreactors,” Biotechnol. Bioeng., vol. 103, no. 4, pp. 733–746, 2009.

- Q. A. Rafiq, K. Coopman, A. W. Nienow, and C. J. Hewitt, “Systematic microcarrier screening and agitated culture conditions improves human mesenchymal stem cell yield in bioreactors,” Biotechnol. J., vol. 11, no. 4, pp. 473–486, 2016.

- B. Li et al., “Past, present, and future of microcarrier-based tissue engineering,” Journal of Orthopaedic Translation. 2015.

- J. G. Carmelo, A. Fernandes-Platzgummer, M. M. Diogo, C. L. da Silva, and J. M. S. Cabral, “A xeno-free microcarrier-based stirred culture system for the scalable expansion of human mesenchymal stem/stromal cells isolated from bone marrow and adipose tissue,” Biotechnol. J., vol. 10, no. 8, pp. 1235–1247, 2015.

- F. Petry, J. R. Smith, J. Leber, D. Salzig, P. Czermak, and M. L. Weiss, “Manufacturing of Human Umbilical Cord Mesenchymal Stromal Cells on Microcarriers in a Dynamic System for Clinical Use,” Stem Cells Int., vol. 2016, pp. 1–12, 2016.

- N. E. Timmins et al., “Closed system isolation and scalable expansion of human placental mesenchymal stem cells,” Biotechnol. Bioeng., vol. 109, no. 7, pp. 1817–1826, 2012.

- Y. Yuan, M. S. Kallos, C. Hunter, and A. Sen, “Improved expansion of human bone marrow-derived mesenchymal stem cells in microcarrier-based suspension culture,” J. Tissue Eng. Regen. Med., vol. 8, no. 3, pp. 210–225, 2014.

- Q. A. Rafiq et al., “Process development of human multipotent stromal cell microcarrier culture using an automated high-throughput microbioreactor,” Biotechnol. Bioeng., vol. in press, Jul. 2017.

- M. F. Q. Sousa et al., “Production of oncolytic adenovirus and human mesenchymal stem cells in a single-use, Vertical-Wheel bioreactor system: Impact of bioreactor design on performance of microcarrier-based cell culture processes,” Biotechnol. Prog., vol. 31, no. 6, pp. 1600–1612, 2015.

- A. Mizukami et al., “Stirred tank bioreactor culture combined with serum-/xenogeneic-free culture medium enables an efficient expansion of umbilical cord-derived mesenchymal stem/stromal cells,” Biotechnol. J., vol. 11, no. 8, pp. 1048–1059, Aug. 2016.

- Q. A. Rafiq et al., “Qualitative and quantitative demonstration of bead-to-bead transfer with bone marrow-derived human mesenchymal stem cells on microcarriers: Utilising the phenomenon to improve culture performance,” Biochem. Eng. J., vol. 135, pp. 11–21, 2018.

- B. Cunha et al., “Exploring continuous and integrated strategies for the up- and downstream processing of human mesenchymal stem cells,” J. Biotechnol., vol. 213, pp. 97–108, Nov. 2015.

- B. Cunha, M. Serra, C. Peixoto, M. Silva, M. Carrondo, and P. Alves, “Designing clinical-grade integrated strategies for the downstream processing of human mesenchymal stem cells,” BMC Proc., vol. 7, no. Suppl 6, p. P103, 2013.

- A. W. Nienow, Q. A. Rafiq, K. Coopman, and C. J. Hewitt, “A potentially scalable method for the harvesting of hMSCs from microcarriers,” Biochem. Eng. J., vol. 85, pp. 79–88, 2014.

- A. M. de Soure et al., “Integrated culture platform based on a human platelet lysate supplement for the isolation and scalable manufacturing of umbilical cord matrix-derived mesenchymal stem/stromal cells,” J. Tissue Eng. Regen. Med., vol. 11, no. 5, pp. 1630–1640, May 2017.

- S. F. H. de Witte et al., “Aging of bone marrow– and umbilical cord–derived mesenchymal stromal cells during expansion,” Cytotherapy, vol. 19, no. 7, pp. 798–807, 2017.

- A. T.-L. Lam et al., “Biodegradable poly-ε-caprolactone microcarriers for efficient production of human mesenchymal stromal cells and secreted cytokines in batch and fed-batch bioreactors,” Cytotherapy, vol. 19, no. 3, pp. 419–432, Mar. 2017