当前位置

Bioprinting MSC in Outer Space

During the summer of 2023, an important frontier was crossed for the first time when Mesenchymal Stromal Cells (MSC) were successfully bioprinted into a human knee meniscus in the weightless environment onboard the International Space Station (ISS). Like all research on the ISS, it took a team of collaborators to make this achievement possible. The biomedical research division of the Uniformed Services University (4DBio3) conducted the medical experiment, out of a motivation to create improved therapies for injuries like meniscus tears that are common among service members. The 3D BioFabrication Facility in which the cells were grown was built by Redwire, a company that is dedicated to accelerating the expansion of humanity into space by providing technology for the next generation space economy. Their 3D printing device subsequently won a 2023 Popular Science Best of What’s New Award. The seed MSC for the experiment came from Ready-to-Print (RTP)® cell vials supplied by RoosterBio. The RoosterRTP product is specifically designed to provide MSC as ink for bioprinters; each vial holds 50 million cells that are quality-controlled, characterized for reliable performance, and ready to thaw and print. Finally, Dragon rockets from SpaceX ferried the supplies to the ISS and then after the mission brought back the crew, the equipment, and the new meniscus.

During the summer of 2023, an important frontier was crossed for the first time when Mesenchymal Stromal Cells (MSC) were successfully bioprinted into a human knee meniscus in the weightless environment onboard the International Space Station (ISS). Like all research on the ISS, it took a team of collaborators to make this achievement possible. The biomedical research division of the Uniformed Services University (4DBio3) conducted the medical experiment, out of a motivation to create improved therapies for injuries like meniscus tears that are common among service members. The 3D BioFabrication Facility in which the cells were grown was built by Redwire, a company that is dedicated to accelerating the expansion of humanity into space by providing technology for the next generation space economy. Their 3D printing device subsequently won a 2023 Popular Science Best of What’s New Award. The seed MSC for the experiment came from Ready-to-Print (RTP)® cell vials supplied by RoosterBio. The RoosterRTP product is specifically designed to provide MSC as ink for bioprinters; each vial holds 50 million cells that are quality-controlled, characterized for reliable performance, and ready to thaw and print. Finally, Dragon rockets from SpaceX ferried the supplies to the ISS and then after the mission brought back the crew, the equipment, and the new meniscus.

As described in a blog for RoosterBio, space is now the final frontier for MSC bioprinting1. The microgravity of Earth orbit makes it possible to grow bioengineered materials that cannot be created on Earth. It is well known that MSC are an “adherent” cell type, and most of them will die if they cannot cling to a surface2. This is why many academic laboratories grow MSC on large numbers of plates, a labor-intensive process that cannot readily be scaled up. Pharmaceutical companies that need large quantities of MSC for off-the-shelf therapeutic products have scaled up production in bioreactors. But the need for cell adherence remains, and bioreactors accommodate that need with a variety of methods: stirred tanks holding microcarriers, rotating hollow fibers, etc.3. Regardless of how the MSC are grown, the next step in creating organs is to somehow deposit them into a 3D structure. One way to do this is to provide a scaffold to which the adherent cells can cling. Scaffolds have been used to grow body parts ranging from simple structures like a bone, up to an entire human heart4,5. However, the challenge of growing functional new organs from cells arises when the tissue layers are more than a few cells thick; at this point the cells do not deposit evenly and they need blood vessels to nourish them.

As described in a blog for RoosterBio, space is now the final frontier for MSC bioprinting1. The microgravity of Earth orbit makes it possible to grow bioengineered materials that cannot be created on Earth. It is well known that MSC are an “adherent” cell type, and most of them will die if they cannot cling to a surface2. This is why many academic laboratories grow MSC on large numbers of plates, a labor-intensive process that cannot readily be scaled up. Pharmaceutical companies that need large quantities of MSC for off-the-shelf therapeutic products have scaled up production in bioreactors. But the need for cell adherence remains, and bioreactors accommodate that need with a variety of methods: stirred tanks holding microcarriers, rotating hollow fibers, etc.3. Regardless of how the MSC are grown, the next step in creating organs is to somehow deposit them into a 3D structure. One way to do this is to provide a scaffold to which the adherent cells can cling. Scaffolds have been used to grow body parts ranging from simple structures like a bone, up to an entire human heart4,5. However, the challenge of growing functional new organs from cells arises when the tissue layers are more than a few cells thick; at this point the cells do not deposit evenly and they need blood vessels to nourish them.

Bioprinting organs in a weightless environment can solve some challenges, while at the same time new challenges are encountered. In low Earth orbit, objects on the ISS are constantly free falling at 17,500 miles per hour and there is no danger that layers of cells will sag under their own weight. But when building any implant or organ using MSC, the cells still need to adhere to something. One way to do this is by 3D printing MSC suspended in a biological ink where the MSC cling to components in the ink base. “Bioinks are predominantly based on hydrogels which must fall within the so-called biofabrication window, as they have to be dimensionally stable enough for 3D printing of constructs with high shape fidelity and at the same time soft enough to allow for the embedded cells to survive and function”6. For example, the first bioink approved for use in space is based on a blend of alginate (a naturally occurring polymer obtained from seaweed) with cellulose6. Working in space, MSC bioinks can be used to print organs with very evenly distributed cells that are not subject to sedimentation. This type of tissue engineering is not possible on Earth.

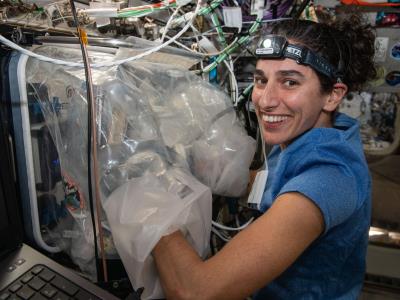

Efforts to bioprint in space are still in the experimental phase, which is why the first meniscus grown from RoosterBio’s previously cryopreserved MSC was such a big achievement. The existing technologies for bioprinting have been calibrated on the surface of the Earth, hence the environment of space presents many new challenges for the development of robust devices and procedures. In space, you can still extrude or jet out a droplet, but you cannot expect that the droplet will fall under gravity. “In space, flow distances and rates, droplet sizes, and fluid surface tensions all exhibit radically different behaviors. Sub-millimeter-sized bubbles in fluids can be an insidious problem, as these cannot simply fizz to the surface and pop”1. This is why it is necessary to design new equipment, like Redwire’s 3D BioFabrication Facility, for bioprinting in space. Safety precautions during space manufacturing are also big concern, because any fluid leaks will spread in all directions, not just spill down to the floor. This is why the bioprinting equipment is operated inside a closed fabrication hood on the ISS (see the NASA photo of ISS astronaut Jasmin Moghbeli working with the BioFabrication Facility).

Efforts to bioprint in space are still in the experimental phase, which is why the first meniscus grown from RoosterBio’s previously cryopreserved MSC was such a big achievement. The existing technologies for bioprinting have been calibrated on the surface of the Earth, hence the environment of space presents many new challenges for the development of robust devices and procedures. In space, you can still extrude or jet out a droplet, but you cannot expect that the droplet will fall under gravity. “In space, flow distances and rates, droplet sizes, and fluid surface tensions all exhibit radically different behaviors. Sub-millimeter-sized bubbles in fluids can be an insidious problem, as these cannot simply fizz to the surface and pop”1. This is why it is necessary to design new equipment, like Redwire’s 3D BioFabrication Facility, for bioprinting in space. Safety precautions during space manufacturing are also big concern, because any fluid leaks will spread in all directions, not just spill down to the floor. This is why the bioprinting equipment is operated inside a closed fabrication hood on the ISS (see the NASA photo of ISS astronaut Jasmin Moghbeli working with the BioFabrication Facility).

Despite the high costs of lifting cells and equipment into low Earth orbit (LEO) and bringing them back, bioprinting organs in space makes financial sense. Currently, the cheapest cost per kilogram to lift materials up to LEO is about $2,000. Heavy lift vehicles that are currently in development are promising to reduce that cost to $100 per kilogram, making industrial parks in LEO feasible. As compared to the prices of high-end life science products, this is not expensive. “One extreme example is the ubiquitous Taq polymerase enzyme, priced at around $100 per microgram…or a mere $100 billion per kilogram…over 1.5 million times the price of solid gold”1. Meanwhile, thousands of patients per year are dying in the United States while waiting on organ transplant waiting lists7. If life-saving organs for transplant can be grown in space, the cost-to-benefit ratio of this endeavor will probably favor biological manufacturing in space.

Despite the high costs of lifting cells and equipment into low Earth orbit (LEO) and bringing them back, bioprinting organs in space makes financial sense. Currently, the cheapest cost per kilogram to lift materials up to LEO is about $2,000. Heavy lift vehicles that are currently in development are promising to reduce that cost to $100 per kilogram, making industrial parks in LEO feasible. As compared to the prices of high-end life science products, this is not expensive. “One extreme example is the ubiquitous Taq polymerase enzyme, priced at around $100 per microgram…or a mere $100 billion per kilogram…over 1.5 million times the price of solid gold”1. Meanwhile, thousands of patients per year are dying in the United States while waiting on organ transplant waiting lists7. If life-saving organs for transplant can be grown in space, the cost-to-benefit ratio of this endeavor will probably favor biological manufacturing in space.

The long-term hope is that humankind will colonize space. The ability to grow cells onboard spaceships will be a critical component of the medical toolbox for long-haul astronauts8. During a long journey in space, astronauts will need to survive repeated exposure to ionizing radiation. They will need to overcome the debilitating medical effects of prolonged weightlessness. And, of course they will need cures if they get sick with cancer or organ failure. On top of all that, astronauts will need food to eat, and lab-grown meat will probably be part of their diet9,10. For now, overcoming the challenges of bioprinting MSC in orbit is the first step towards these long-term ambitious goals.

References:

- Carson J. The Final Frontier for Mesenchymal Stem/Stromal Cells. RoosterBio blog Published 2023-11-20

- Lee S, Choi E, Cha MJ, Hwang KC. Cell Adhesion and Long-Term Survival of Transplanted Mesenchymal Stem Cells: A Prerequisite for Cell Therapy. Oxid. Med Cell Longevity 2015; 2015:632902.

- Silva Couto P, Rotondi MC, Bersenev A, Hewitt CJ, Nienow AW, Verter F, Rafiq QA. Expansion of human mesenchymal stem/stromal cells (hMSCs) in bioreactors using microcarriers: lessons learnt and what the future holds. Biotechnology Advances 2020; 45:107636.

- Levin D. Stanford bioengineers aim to build a heart, one layer at a time. Stanford news. Published 2022-03-14

- Morrissey J, Mesquita FCP, Hochman-Mendez C, Taylor DA. Whole Heart Engineering: Advances and Challenges. Cells Tissues Organs 2022; 211 (4):395–405.

- Windisch, J, et al. Bioinks for Space Missions: The Influence of Long-Term Storage of Alginate-Methylcellulose-Based Bioinks on Printability as well as Cell Viability and Function. Adv. Healthcare Materials. 2023; 12(23):e2300436.

- Donate Life America. Organ, Eye and Tissue Donation Statistics. Accessed 2024-01-01

- Giri J, Moll G. MSCs in Space: Mesenchymal Stromal Cell Therapeutics as Enabling Technology for Long-Distance Manned Space Travel. Current Stem Cell Reports. 2022; 8(1):1-13.

- Benayahu D. Mesenchymal stem cell differentiation and usage for biotechnology applications: tissue engineering and food manufacturing. Biomaterials Transl. 2022; 3(1):17–23.

- Thompson, J. Lab-Grown Meat Approved for Sale: What You Need to Know. Scientific American Published 2023-06-30